The QMS should be designed in such a way as to provide the necessary information to manage the business.

An effective QMS will help you:

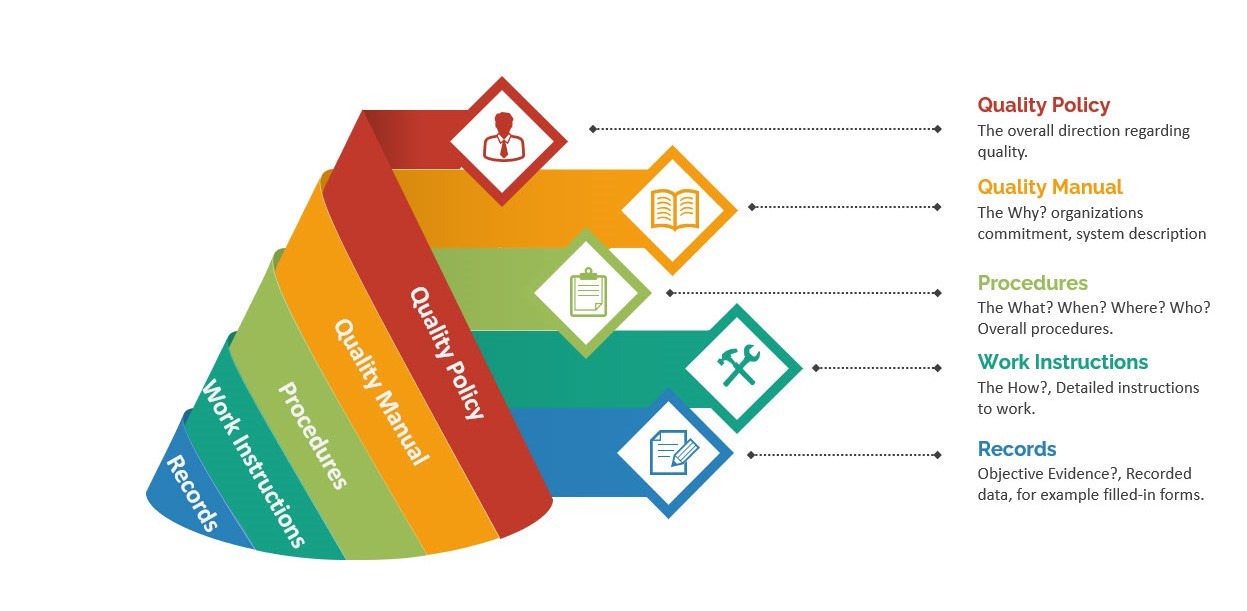

The purpose of this document is to describe the components of an effective QMS that will allow you to meet your objectives. Typical elements of QMS include Quality Policy, Quality Manual, Procedures, Work Instructions and Records.

Quality Policy is a document developed by management to express the organization’s overall direction. It provides a framework for quality objectives and includes a commitment to meet applicable requirements as well as to improve continually.

It states what the company stands for and should be aligned with the organization’s mission and vision statement or value proposition.

Your quality manual defines the overview of procedures by which your organization will operate. This includes all aspects of the quality management system. The levels of details and the manual’s format will depend on the type of organization.

They outline specific activities that must be performed at each step along the production process. A procedure describes the sequence of operations required to produce a product. Procedures aim to deliver efficient, high-quality outputs and ensure compliance with industry regulations.

Work Instructions are written documents that contain step-by-step descriptions of how to perform a task. They are sometimes referred to as “how-to” instructions. These instructions should be used in conjunction with other tools such as manuals, procedures, and records.

Records serve as documentation of activity and are essential for recording and reporting on the status of various activities. Examples of records could include purchase orders, invoices, inspection reports, test results, and defect data.

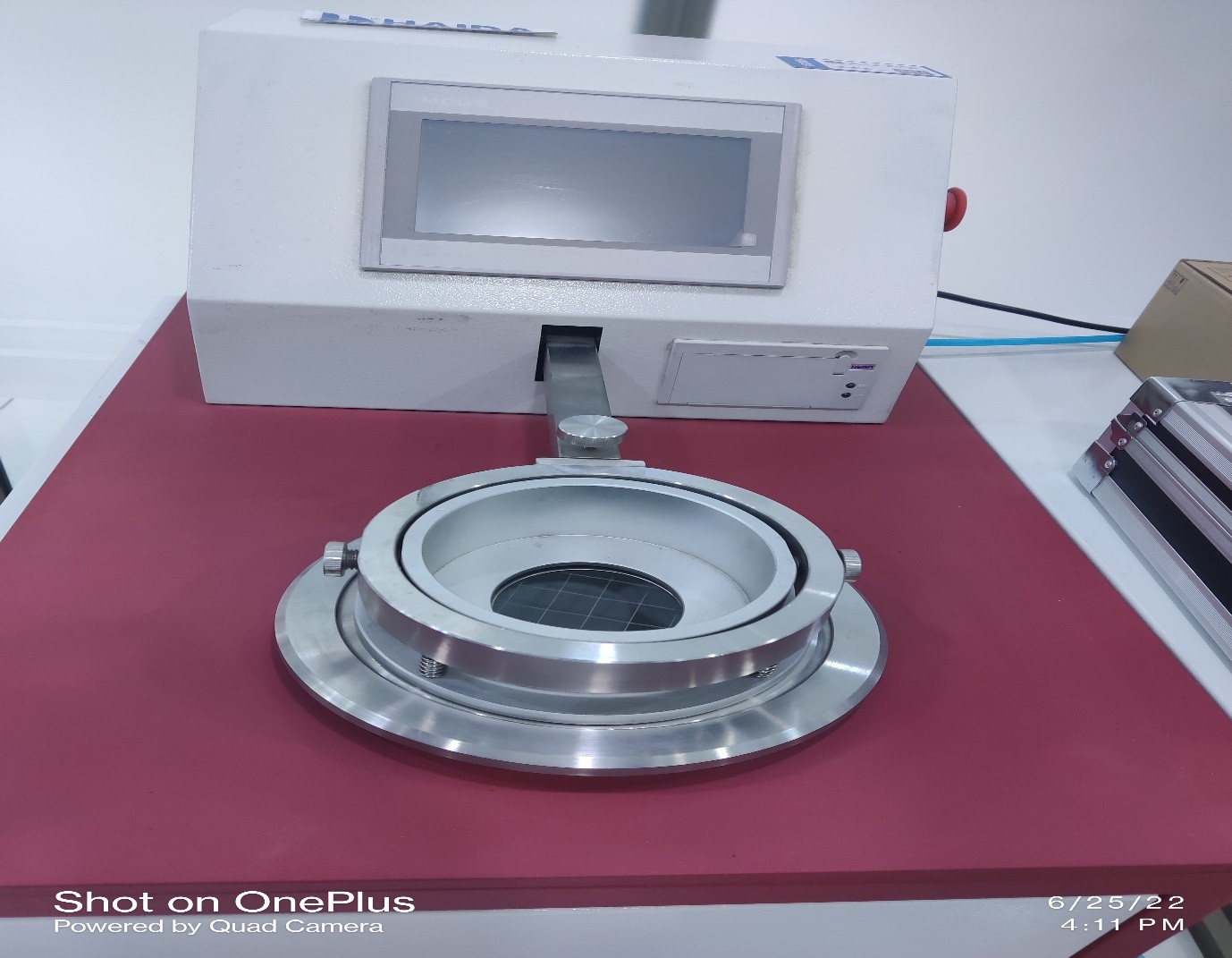

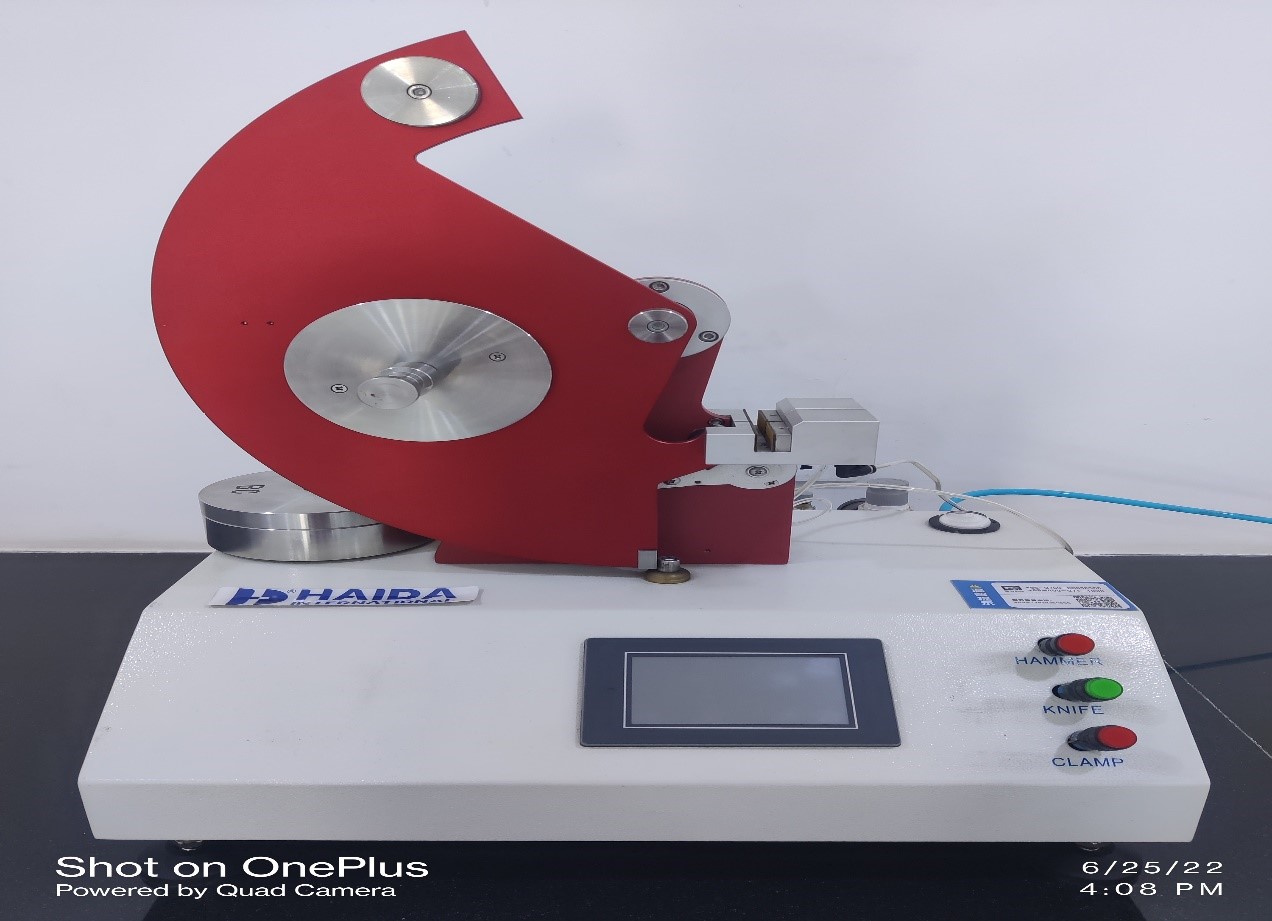

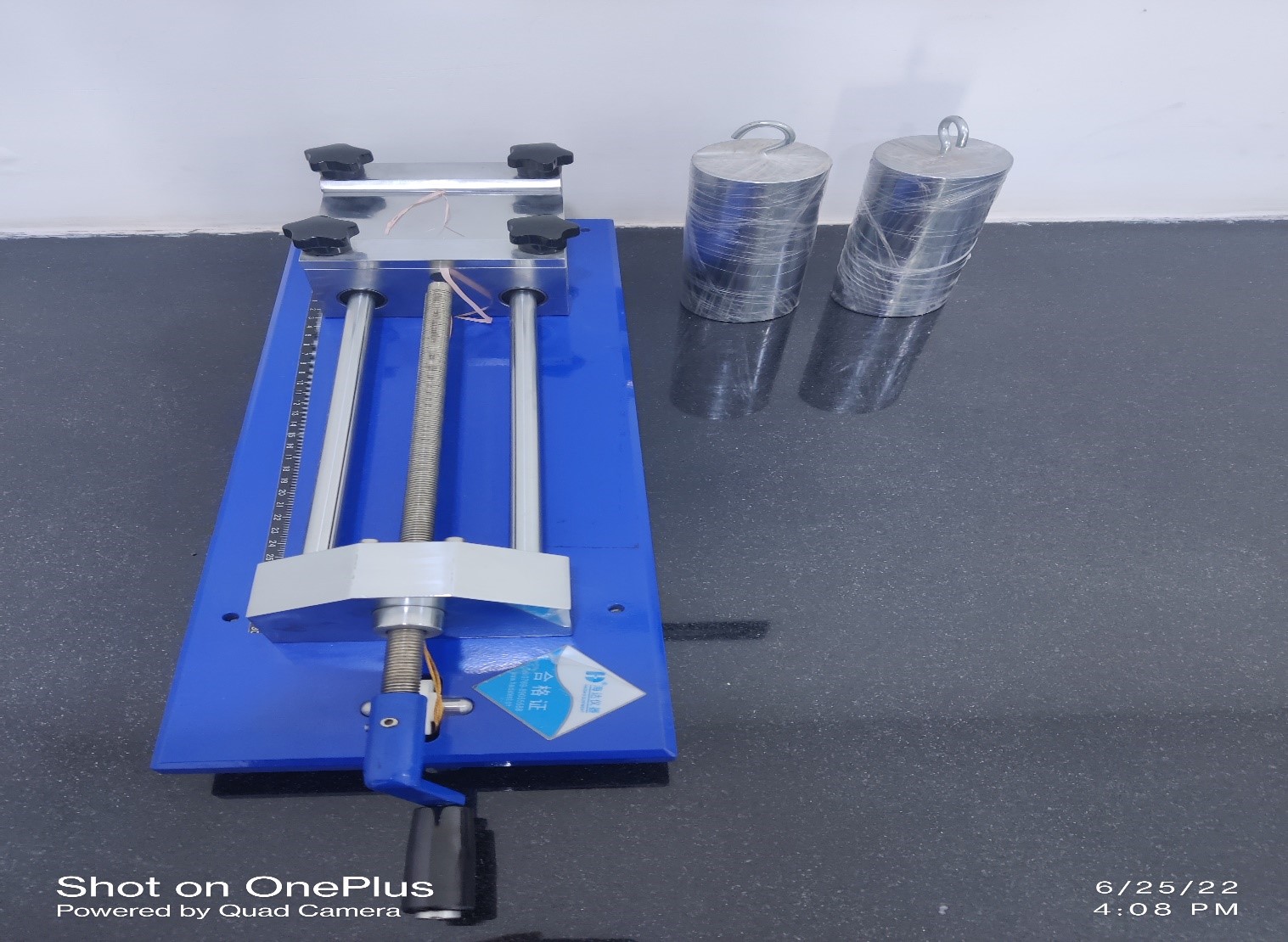

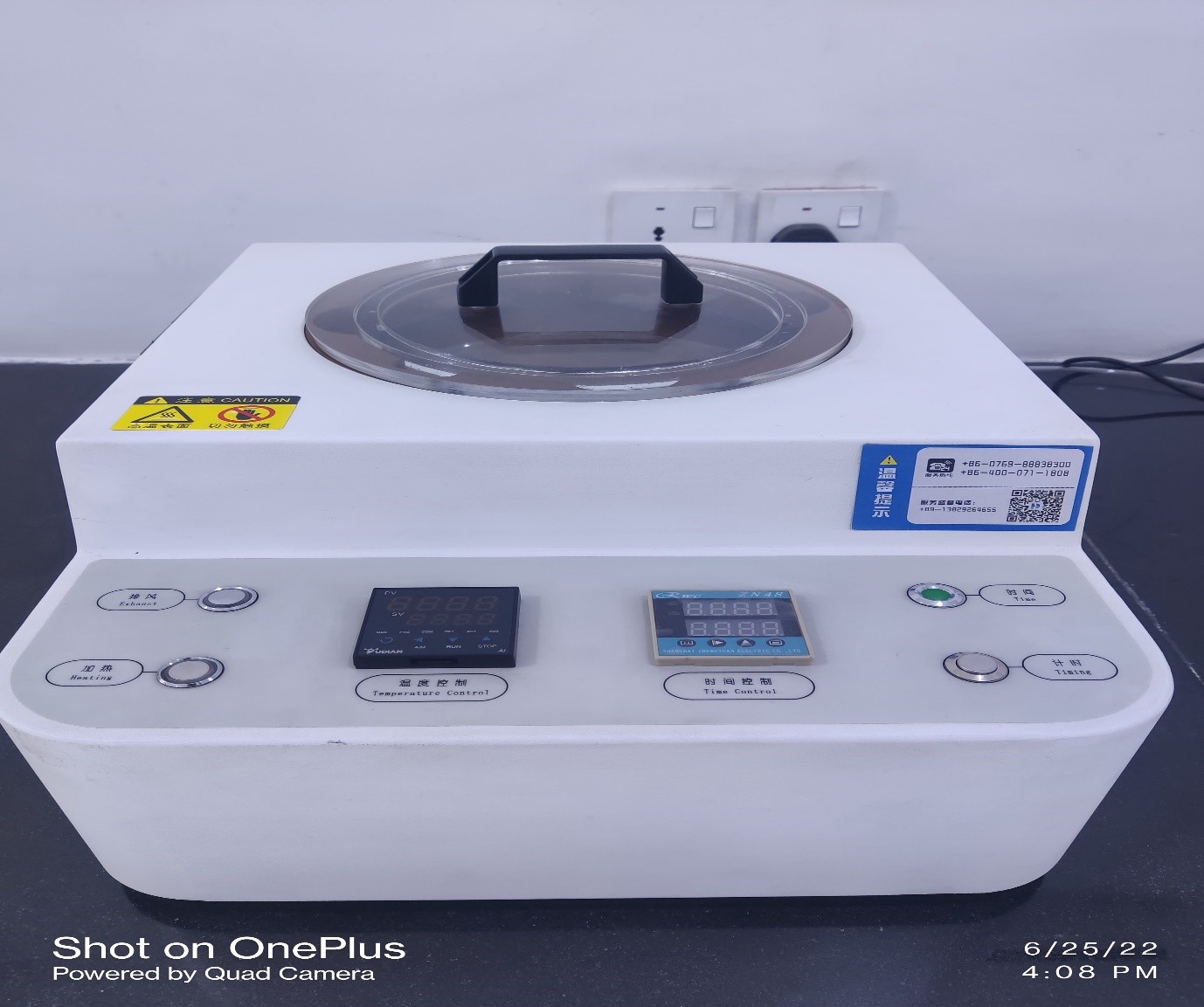

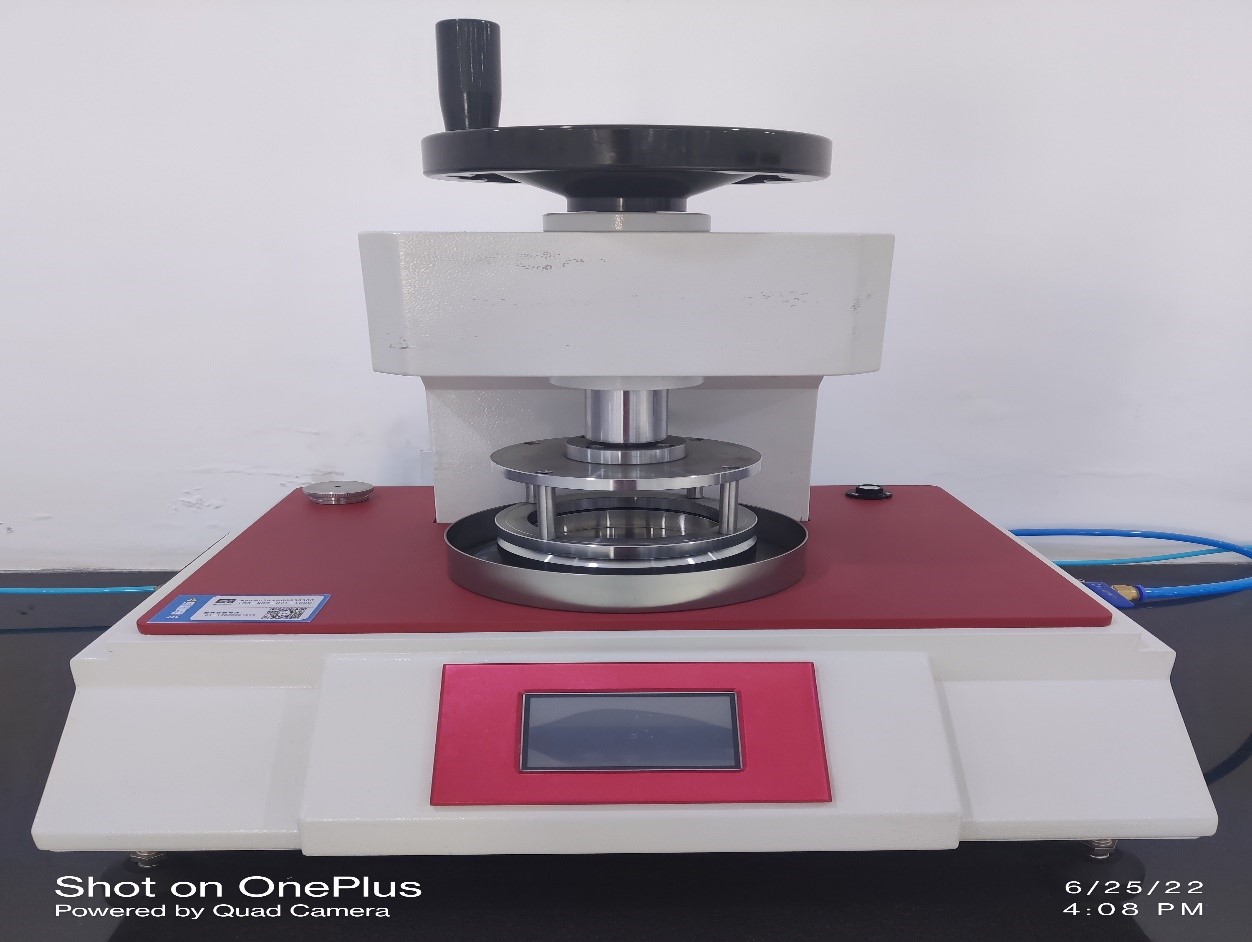

Along with the implementation of QMS product is also needs to tested with physical tools and equipment’s to ensure every product meet specification before it can deliver to the customer with back tracking system of the lab.

Jilani group has setup a centralized lab having more 25 state of the art equipment for the testing of tarpaulin, flexible packaging, non-woven, woven bags and printing Products. There is a system implemented in line with ASTM 17025 according to which is lab is operated. With trained staff and equipment, we have always looked to do more than just testing of the product.

Innovation is what we strive to do, to give our customer economical product with better properties which is always keep us motivated.

Incoming sample is categorized in internal and external sample. After that is it is put to the conditioning in controlled environment. After that sample put to test according to the required testing by the department or customer. After testing results are compiled and segregated according to the specified category. Test report is then compiled for customer.

+92-42-111-200-600